Why you should consider a job at CELSA STEEL UK as your next career move

About CELSA STEEL UK

CELSA STEEL UK started their relationship with South Wales back in 2003 with the acquisition of the Allied Steel & Wire assets in Cardiff. The business is one of the UK’s largest manufacturers of steel long products. Employing roughly 1200 colleagues from 18 sites in the UK. There is a commitment to the safe, sustainable production of steel products for the construction market. Please visit the media gallery and the About Us video for an insight into life within the company.

The business has been involved with some of the UK’s largest infrastructure projects, and you can find out more about them by watching the video below.

Stability

- Having invested an estimated £150M in the Cardiff facility since 2003, CELSA STEEL UK’s long-term commitment to South Wales is clear.

- They have never made any redundancies even during difficult market conditions.

- CELSA STEEL UK is part of the CELSA GROUP, which has a 50-year track record in the steel sector.

- 90% of all steel produced is sold in UK markets.

Jobs & careers at CELSA STEEL UK

- Mechanical and electrical engineers and craftsmen

- Supply chain and logistics professionals, buyers, planners, logistics officers, transport planners, warehouse managers, logistics managers and purchasing managers.

- Health and safety professionals.

- Commercial professionals, including administrators, customer service advisors, etc.

- Production, production operators, production supervisors, shift managers, and production managers.

Interested in a job at CELSA? Submit a CV online for jobs at CELSA here (Please put “CELSA” as the job reference number)

Health and Safety at CELSA STEEL UK

- They are committed to the highest standards of health and safety.

- The Health & Safety of all those who work at the company is the main priority of the business, along with the impact they have on the wider environment. There is a strong link between health, safety, and employee welfare. They have a strategic objective to focus on Health & Safety with the aim to become the industry leader in safety. They are committed to achieving ZERO accidents.

- A strong health and safety team with advisors is attached to the Melt Shop, Sections Mills and the Rod & Bar Mill. This means that the advisors can develop specific knowledge and understand the unique issues that occur in each operating unit. With that understanding, unified by a core safety strategy, the safety advisors are able to better improve the process and behavioural safety of each area.

- The headcount within the HSE team has doubled to offer an even greater level of support to the business.

- Health and Safety performance is benchmarked against some of the most highly regulated sectors, including best-in-class companies.

- The group has recently invested a significant amount of money in improving health & safety, as well as colleague and supplier welfare, including: –

- The introduction of bespoke software packages to manage the company permit-to-work system, interlock and change management processes. Along with specialist software to manage registration and qualification checks for contractors.

- Refurbishment of changing facilities and canteens.

Career development

- As Cardiff’s largest manufacturing company, with over 600 permanent staff, excellent promotion and career development prospects are available.

- Sigma Recruitment has personally seen candidates start as craftsmen and progress all the way to director level!

- The business is an engineering lead company that employs around 120 technicians/engineers in Cardiff alone.

- All crafts team leaders have been developed and promoted internally. With all potential team leaders put through ILM Level 2 management training.

- Study support is available for HNC/HND with some craftsmen who have even gone on to degree level.

- Since 2017, 5 craftsmen have been promoted to the engineering management team.

Investment in people

- Keen to invest in relevant training and or further education.

- Believe in building the UK’s future on UK manufacturing, by offering highly skilled jobs to local communities.

- Past winners of the VSP Employer of the Year award.

- Currently, hold a bronze award in “investors in people” and are aiming for the gold award.

Culture

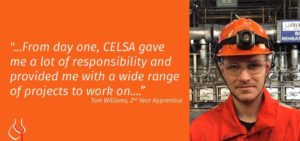

- CELSA STEEL UK believe in empowering colleagues and can offer a high degree of autonomy.

- The culture is close-knit, and colleagues are treated like family.

- Your views will be taken on board and respected by management.

Sustainability, responsible sourcing and community.

- Finished products contain 98% recycled content and are made from 100% UK-sourced scrap.

- Recycle over 1 million tonnes of scrap a year, which they remanufacture into steel products.

- Currently, recycle 95% of the waste generated from their steel production process.

- CELSA STEEL UK has launched an accelerator to help local innovators.

- Are committed to responsible sourcing.

- An award-winning company that has won “Best Overall Business” and “Green Business of the Year” at the Cardiff Business Awards 2018

- Proud to be an “anchor company” sitting alongside some of the largest businesses in Wales.

- View the energy and environment policy

CELSA STEEL UK’s investments in South Wales

- The Welsh Government supports CELSA STEEL UK with a £1.6M investment.

- In 2006, the business invested £150M in a new melt shop to increase production capacity and improve environmental efficiency.

- In 2017, an announcement of plans to invest another £3.5M in its facilities was made.

CELSA STEEL UK’s people

Read about members of the team and their journeys with the company.

Culture and values

- A family culture that promotes empowerment and autonomy.

- Fast-paced environment – with quickly changing priorities.

The steelmaking process

Find out how CELSA STEEL UK turn scrap metal into steel using their modern electrical arc furnace.

The Cardiff Sites

The Melt Shop – Tremorfa – Cardiff

The business manufactures steel via the Electric Arc Furnace (EAF) route. This means that every Tonne of steel produced has been made almost entirely from recycled scrap metal. The EAF has the capacity to produce over 100 Tonnes per hour, giving a yearly production capacity of around 1,000,000T. The furnace consumes approximately 285 MW Hours of power each year, which is the eq of 52% of Cardiff’s electricity requirements! 82% of all electricity consumed comes from renewable energy.

Products

- Steel billet for downstream processing at Rod & Bar and Section Mill’s.

Rod & Bar Mill – Castle Works – Cardiff

The rod and bar mill can produce 890,000 tonnes each year for a wide range of reinforcing and wire rod products. In 2006, there was an investment of £10M for a new four-line spooler mill, making it the first UK mill to produce hot spooled coil, a process vital for achieving grade 500C properties in coil format.

Products

- Reinforcing bar – for the reinforcement of concrete.

- High-yield coils – for the reinforcement of concrete.

- Wire rod – for fencing and bedsprings.

Section Mill – Tremorfa – Cardiff

The section mill can produce 350,000 tonnes of merchant bar and section. It is a 14-stand cross-country mill with a billet reheating furnace that can produce 80 tonnes per hour. The original mill was commissioned in 1964 and updated in 1985 to produce a range of medium steel section products, including angles, flats and channels in a range of sizes and lengths up to 15.5m. Further developments came in 1993 and 1994 when the furnace was reconstructed to use either oil or gas. In 2003, after a successful commissioning period, the mill began producing equal and unequal angles, standard and UPN channels, and flat bars from 50mm to 300mm. In 2006 a new Russula process control system was installed, ensuring tighter tolerances and a greater production volume, as well as extending the product range to include smaller sizes.

Products

- Flat bars – for trailer flats.

- Angles – used in construction, fabrication, and pylon construction.

- Channels – for fabrication, manufacturing and construction.

News

View the latest news and tweets from CELSA STEEL UK.

How to apply for jobs at CELSA STEEL UK, Cardiff.

- Submit a CV online for jobs at CELSA here (Please put “CELSA” as the job reference number)

- Email a CV for jobs at CELSA to ads@www.sigmarecruitment.co.uk

- Call us on 02920 450100 to discuss jobs at CELSA

Sigma Recruitment and CELSA

Sigma Recruitment has been working on jobs at CELSA STEEL UK since 2005.

“I started recruiting for the organisation in 2005. I have personally seen candidates that I have placed progress from purchasing assistant level to group purchasing manager in a short space of time. Over the last 13 years, I have witnessed the company’s commitment to steelmaking in Cardiff. The business is clearly in it for the long term and has never made any redundancies, even during difficult market conditions. I have been impressed with the commitment to recycling, continuous improvement and responsible sourcing”

Rhys Williams, managing director of Sigma Recruitment Ltd. You can find out more about Sigma Recruitment in Cardiff here